This article was originally published anonymously on EWCP’s defunct satirical FRC news blog MentorBuilt.com late in the Fall 2018 offseason. On July 9, 2020, this author revealed his involvement as part of the team which wrote this article.

Throughout this post, we’ll put the original article into appropriate historical context, discuss the immediate reactions to the article across the FIRST community, and consider the long-term impact of the article on the FRC program. We’ll also look at the motivations for writing and publishing this article anonymously, and discuss the continuing effects of those decisions as well.

– Nate Laverdure

This flaw is bad and needs to be corrected. A radio should not be a pressure-sensitive input device! As we know, “A reboot of the robot radio is typically characterized by a loss of connection to the radio for ~25-30 seconds” or approximately 1/4 the duration of a FRC match.

In this article, MentorBuilt will illustrate a repair which will prevent this behavior.

During the 2018 FRC competition season, this ####shitty radio was rebooting all the time. ####ADD SUPPORTING DATA####

– Nate Laverdure

Let’s get the legality discussion out of the way first

Rule R72 of the 2018 FRC rules generally disallows any modification of the mandatory control system components, including the radio. These devices “shall not be tampered with, modified, or adjusted in any way.” The rule lists the following types of tampering: “drilling, cutting, machining, rewiring, disassembling, painting, etc.” Exception M of the R72 allows these components to be repaired “provided the performance and specifications of the device after the repair are identical to those before the repair.”

The strange behavior of the radio to trigger its own reboot when the enclosure is pushed a certain way is not a design feature. The behavior is certainly not described in the manufacturer’s performance specifications. Instead, it is a serious flaw to be corrected via a repair. Our repair restores the functionality of the device and enables it to perform per the manufacturer’s performance specifications. In this way, our repair meets the R72M exception and is legal per the 2018 FRC rules.

This argument was not intended to hold up to scrutiny. In fact, it was meant to cause argument. We imagined the breakout of widespread moral panic in response to this article’s advocacy for modification of FRC controls electronics, equipment typically held sacred by the FRC rules.

– Nate Laverdure

Flaws and repairs

There are two related mechanisms that may cause the inadvertent reboot of the OM5P-AC FRC radio when an external force deforms the plastic case near the connector end of the device. In the following sections, we’ll describe both the potential sources of the errors and the steps you’ll need to follow to execute a successful repair.

Today’s FRC particpants should now follow the official version of these instructions, found at docs.wpilib.org.

– Nate Laverdure

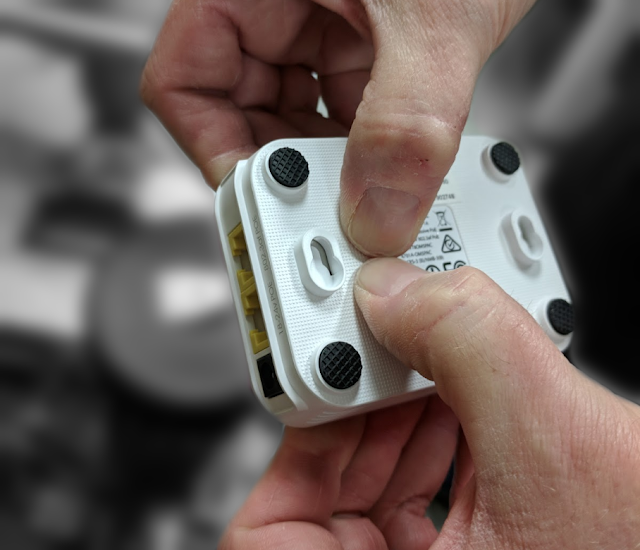

Take care when removing the radio lid to avoid damaging the antennas or their wires.

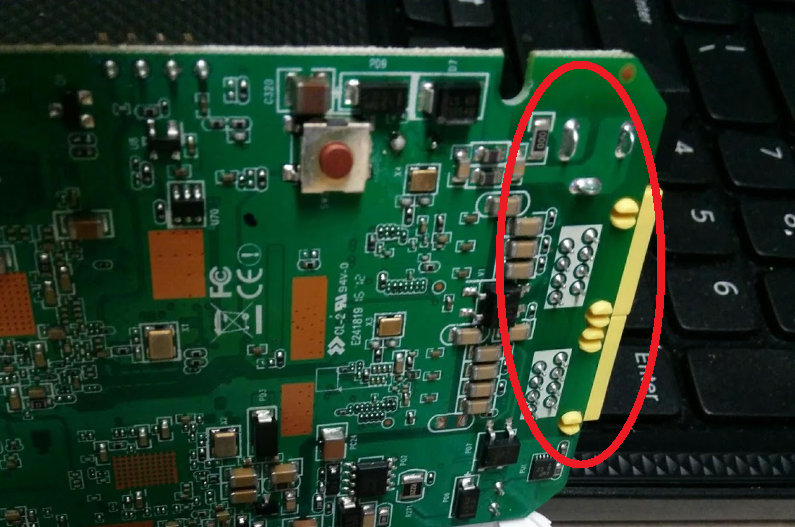

Potential cause 1: Metal shielding plate contacting & shorting connector leads

Some parts of the internal circuit board may be contacting a nearby metal shielding plate and creating an electrical short.

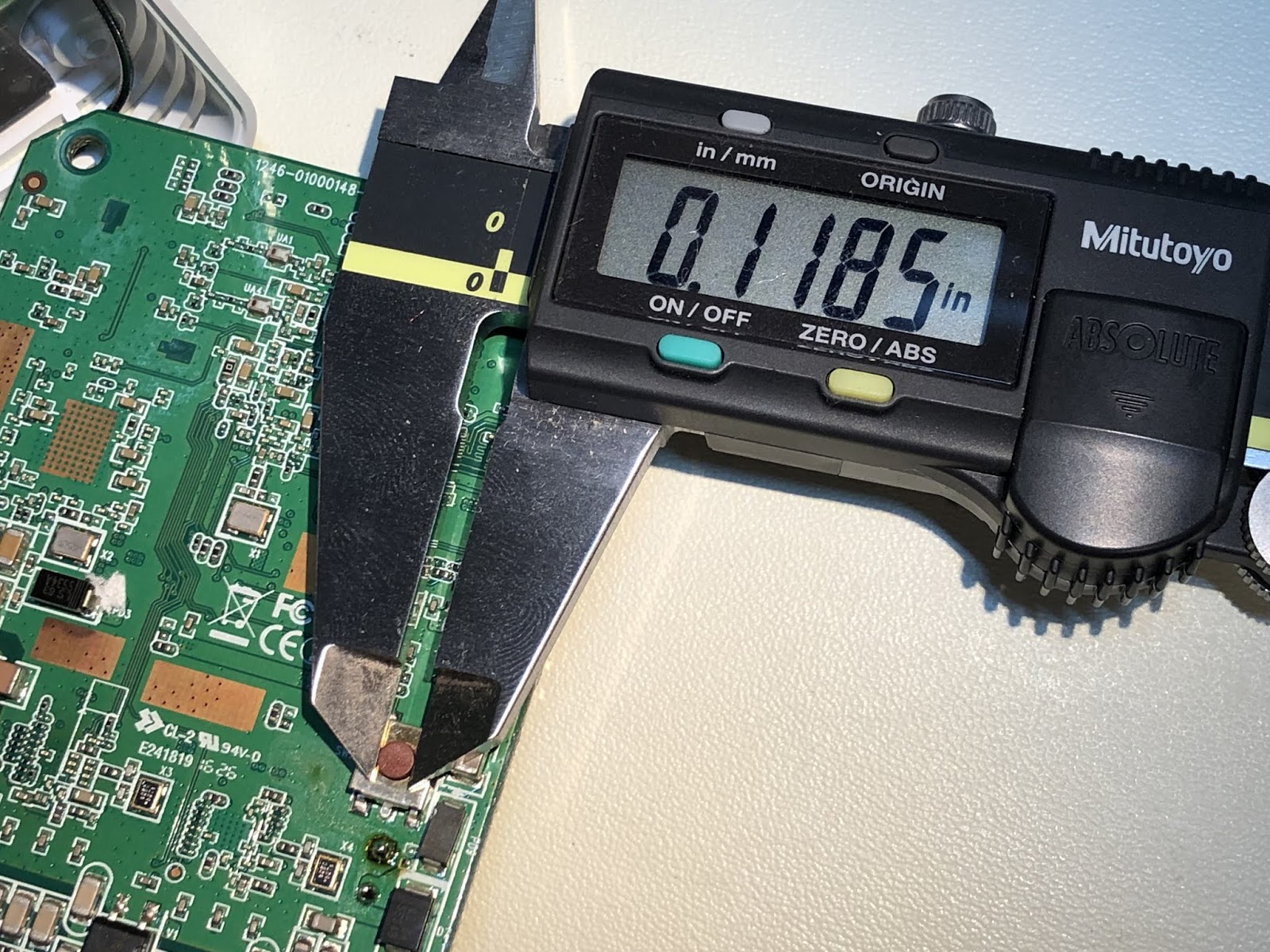

Several through-hole components are soldered to the board in the area of interest: a female barrel connector for power, and two RJ45 connectors for ethernet. Their leads protrude through the board and are soldered from the underside. There is no insulating coating over these pins. When the case deforms, a thin aluminum shielding plate may touch the pins and cause a short.

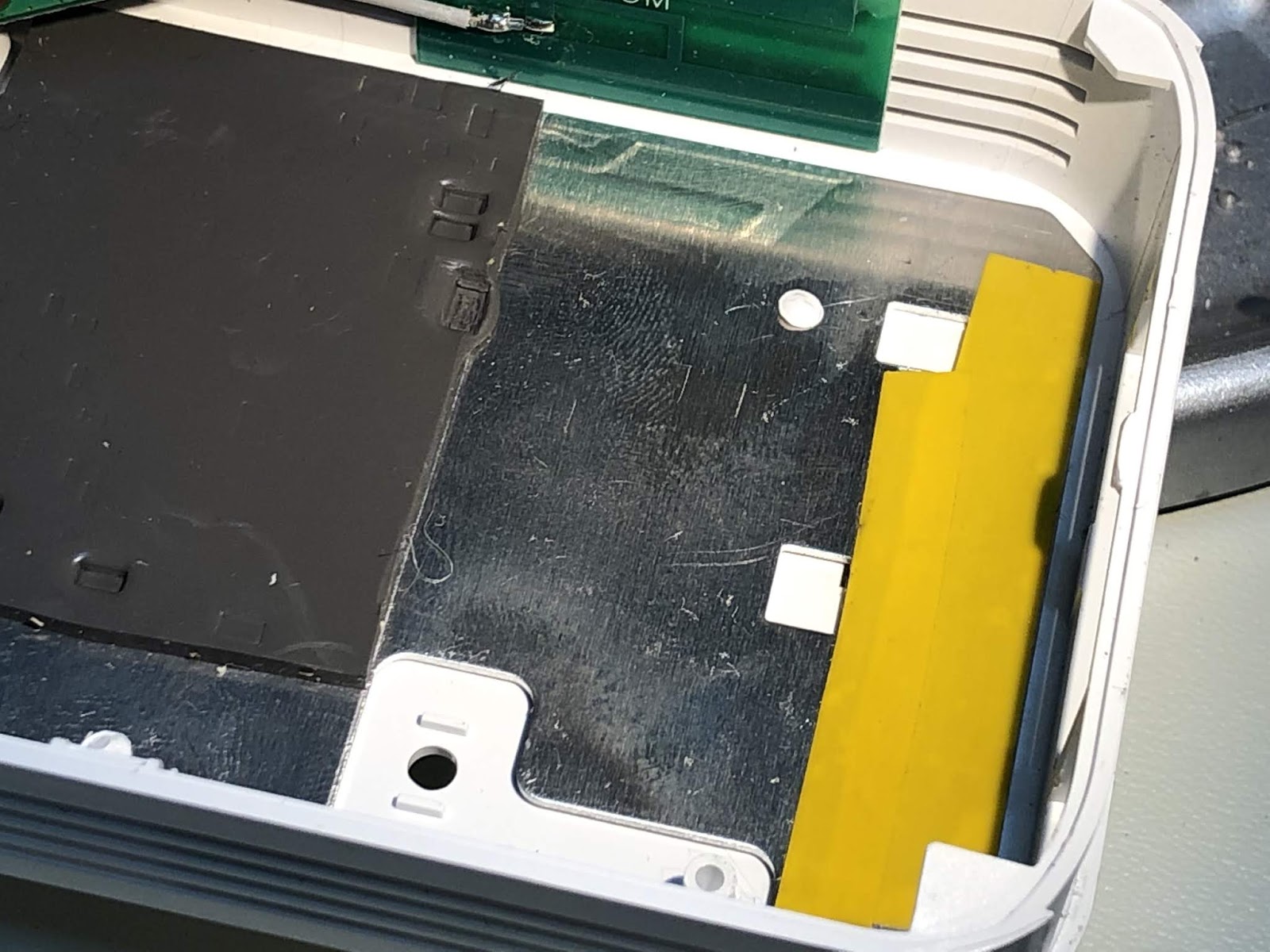

To repair the radio, we apply a piece of electrical tape to the inside of the aluminum shield where the connector pins would touch.

Potential cause 2: Interior of case pressing reset button

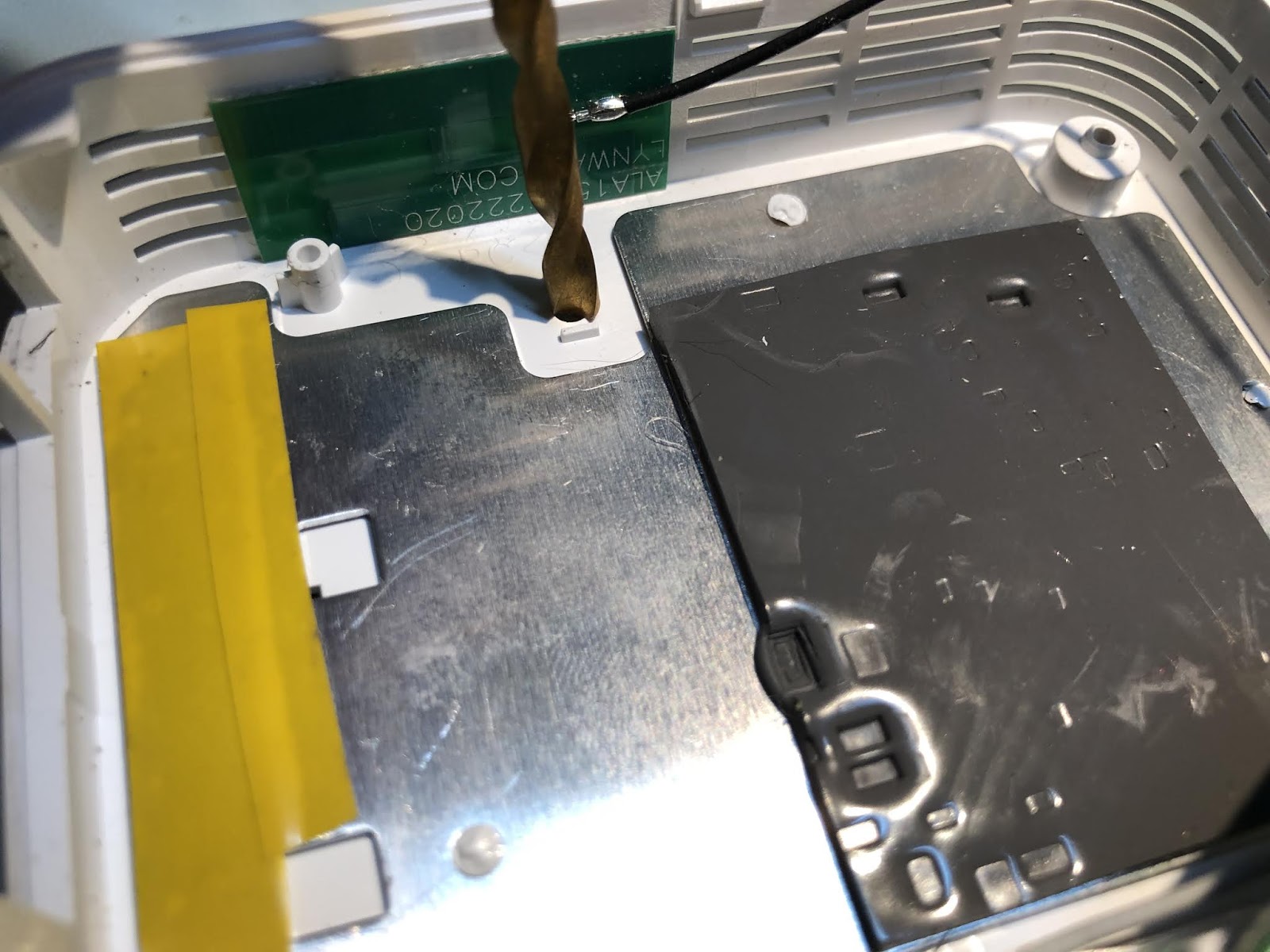

When deformed, the white plastic case itself may inadvertently contact the small red tactile reset button and cause the reboot.

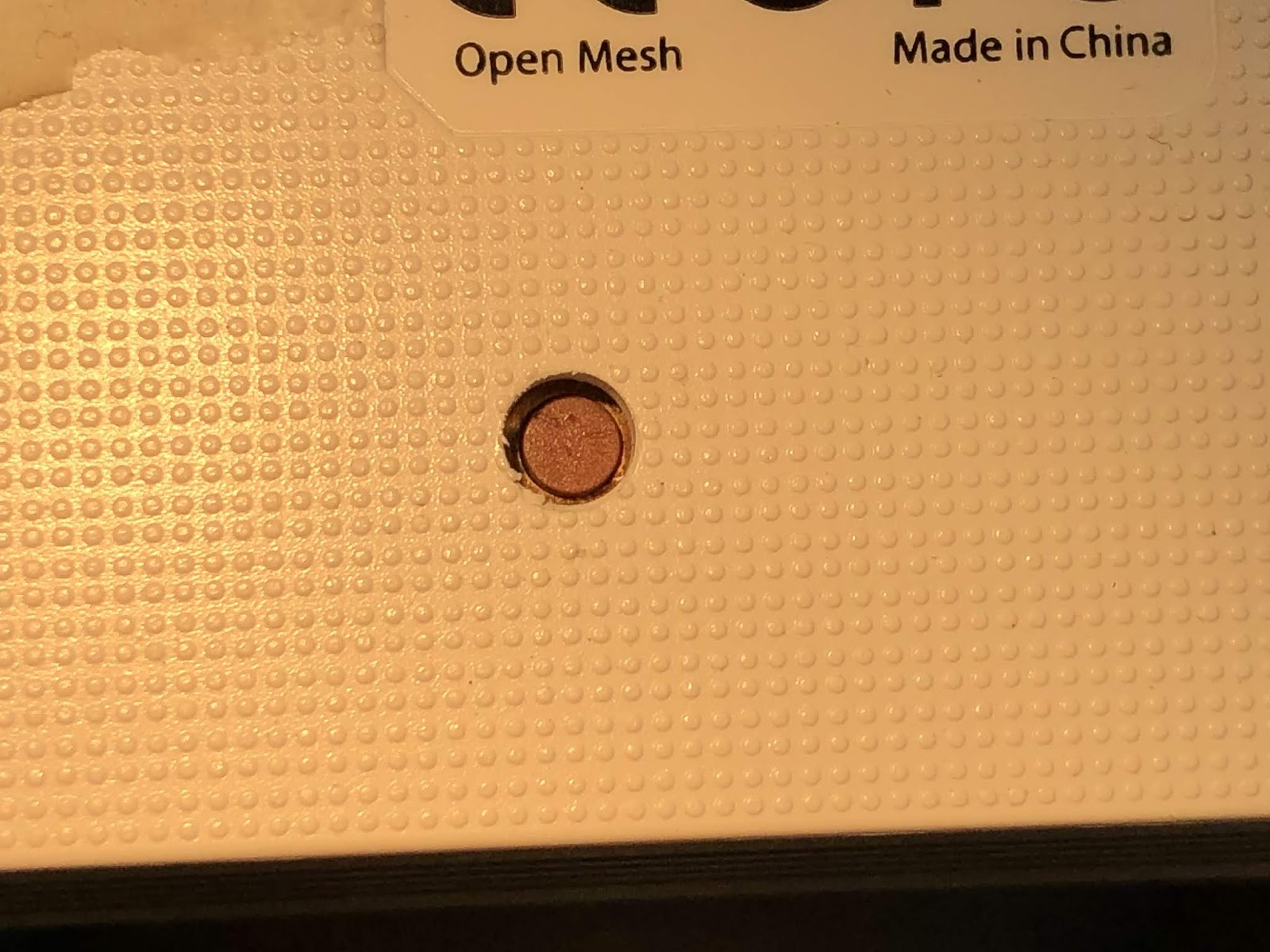

There is hole though the plastic case that enables the user to use a small tool to poke the button. Unfortunately, the reset button is larger than the hole.

To repair the radio, we slightly enlarged this hole. The repair creates sufficient space around the top of the reset button to prevent any contact when the case is deflected by an outside force.

Testing and final recommendation

MentorBuilt performed both parts of this repair to our stock of Open Mesh OM5P-AC FRC radios. For each of these repaired radios, we attempted to cause a reboot by squeezing the case and we found that the reboot no longer occurred.

When we re-opened our repaired radios after this testing, we found evidence that the connector leads did slightly contact the added electrical tape.

MentorBuilt recommends that teams execute both parts of this repair on their 2019 Open Mesh OM5P-AC FRC radios.